Case Studies

Real-world air emission solutions for complex industrial challenges

Our case studies highlight practical, field-proven air pollution control systems for industries with tough chemistry, tight spaces, and strict regulatory limits. Each brief shows the problem, the engineered solution, and measurable outcomes—so you can quickly see how AAT combines deep process knowledge, rugged designs, and reliable performance to solve emissions challenges and keep operations compliant.

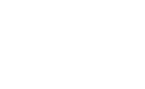

Acid Gas Scrubber Produces 98% Sulfuric Acid

When a major petrochemical producer needed to eliminate hazardous SO₃ emissions from its Oleum process, they turned to AAT for a solution that could do more than just meet regulations, it had to perform flawlessly under extreme conditions. Leveraging decades of experience in complex gas treatment, AAT engineered a custom alloy air scrubber system that not only neutralized emissions, but also converted waste gas into valuable, reusable acid. The result: cleaner air, reliable performance, and a long-term win for both safety and sustainability.

Air Scrubber NOx – Out Nitrogen Dioxide, Clean Air Wins

A leading Midwestern university faced a complex air treatment challenge from its niobium etching labs, where Nitric Acid reactions generated visible NO₂ emissions and regulatory concerns. With strict limits on waste handling, noise, and available space, the project required a precisely engineered solution that balanced performance with efficiency. AAT designed a fully integrated, compact air scrubber system constructed of PVC and reinforced dual-laminate materials, complete with automated airflow modulation for energy savings. Since commissioning in 2014, the system has consistently delivered clean, compliant emissions while supporting ongoing superconducting research operations.

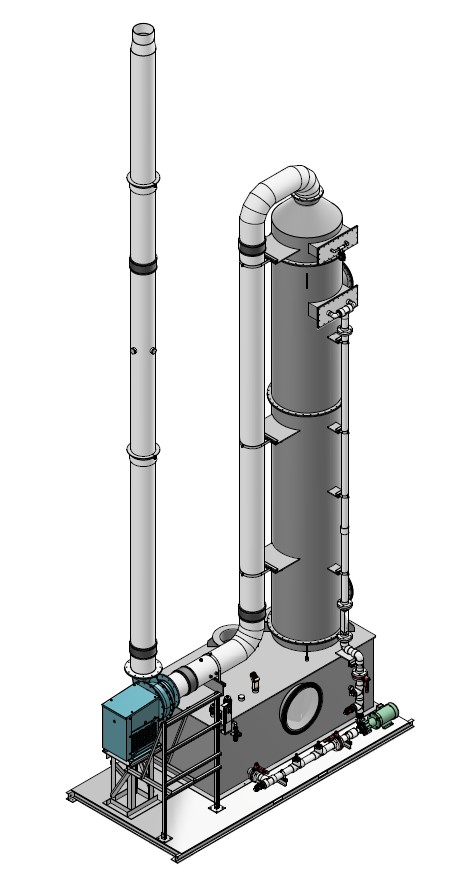

Apollo HCl Air Scrubber Withstands Sub-Zero Temperatures

A major steel mill in a harsh northern environment faced a serious challenge managing Hydrochloric Acid vapors during bulk tank fills. The combination of extreme cold, high vapor concentrations, and strict safety requirements made a standard scrubber unfeasible. AAT’s engineering team designed a rugged, high-efficiency Apollo 500 system using Sodium Hydroxide as the scrubbing medium and specialized mist elimination to prevent HCl fog formation. Fully insulated and electrically heated for arctic operation, the dual-stage venturi and packed-tower design now delivers 99.99% removal efficiency and long-term, trouble-free performance since its 2010 installation.

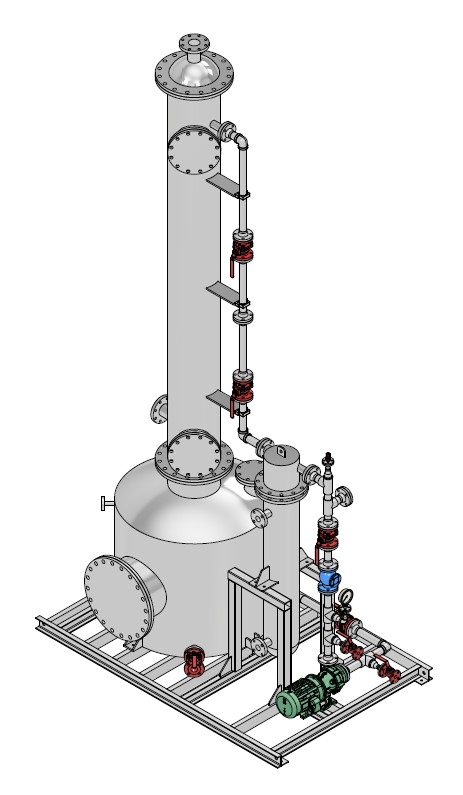

Apollo Scrubber Teams Up with Thermal Oxidizer

A southwestern oil refinery needed a safe, high-efficiency solution for controlling emissions from spent acid storage tanks containing Sulfur Dioxide and n-Propane. Direct venting was prohibited under EPA air quality standards, and the mix of corrosive and flammable gases made treatment complex. AAT engineered an Apollo 250 scrubber system featuring dual-stage venturi and packed-tower operation using Sodium Hydroxide to absorb SO₂, integrated with a vacuum-controlled gas recycle loop and booster fan for precise pressure management. Installed in 2008, the system reliably handles wide flow variations while protecting downstream equipment and ensuring regulatory compliance.

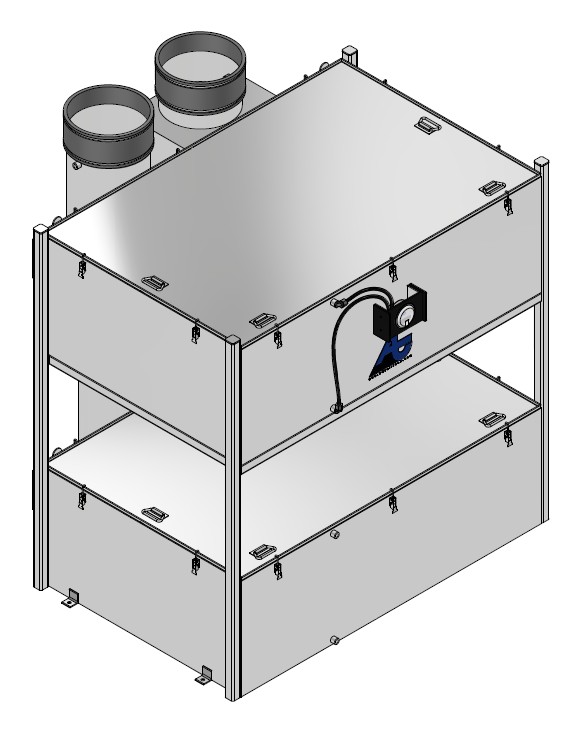

Dry Air Scrubber for Propylene Oxide

For decades, Advanced Air Technologies, Inc. (AAT) has led the industry in dry scrubber technology for the abatement of Ethylene Oxide (EtO) emissions. Founded in 1987 on a unique chemi-sorption process for EtO, AAT’s Safe-Cell II dry scrubber line includes the DR-490 for commercial aeration exhaust, the DR-50 for small hospital sterilizers, and the DR-MAC-150 portable unit for ambient applications. As sterilization processes increasingly turned to Propylene Oxide (PO), AAT set out to verify that Safe-Cell II systems would deliver the same high efficiency, safety, and reliability for this compound as they had long achieved for EtO.

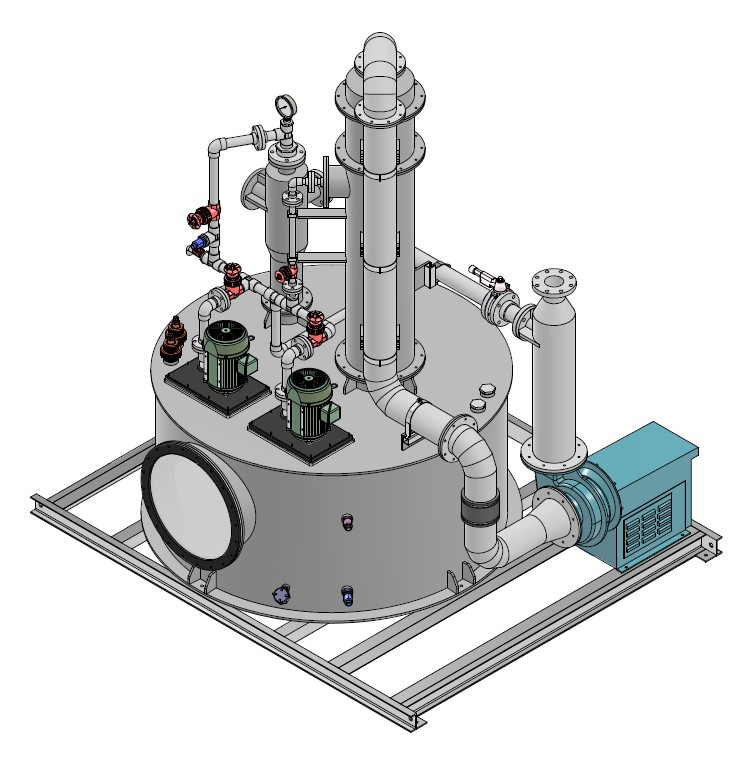

Orion Scrubber Performs Double Duty Application

An overseas gas bottling facility required a versatile, cost-effective system capable of continuously cleaning low-level emissions while mitigating full-cylinder leaks of multiple toxic gases. AAT’s engineered two-stage scrubber package provided acid and base treatment modes, automated chemical control, and fail-safe operation. Installed in 2007, the system exceeded safety targets and led to additional orders for similar units.

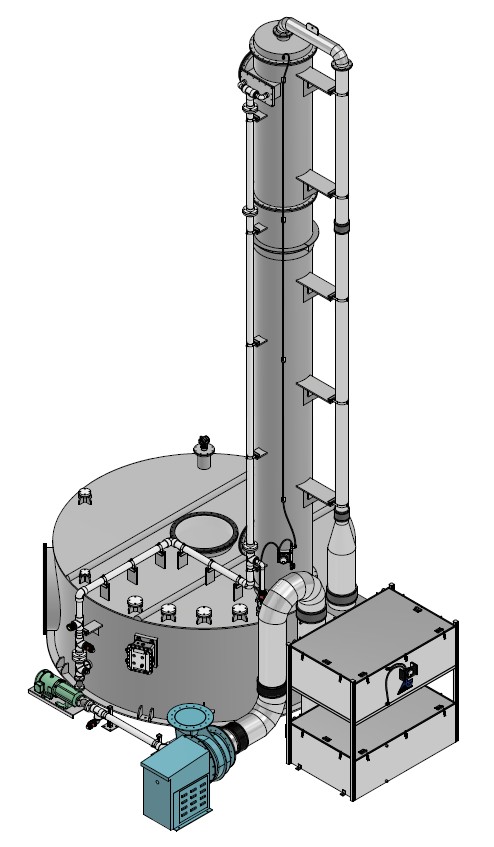

Safe-Cell I & II – The One-Two Punch

Expanding sterilization operations required replacing a costly, high-risk Thermal Oxidizer with a modern alternative that met stringent Ethylene Oxide emission limits. AAT’s dual-stage system, featuring a Plug Flow Reactor wet scrubber followed by a chemisorption dry scrubber, provided exceptional control, easy maintenance, and unmatched performance—setting a new benchmark for safe and sustainable emissions treatment.

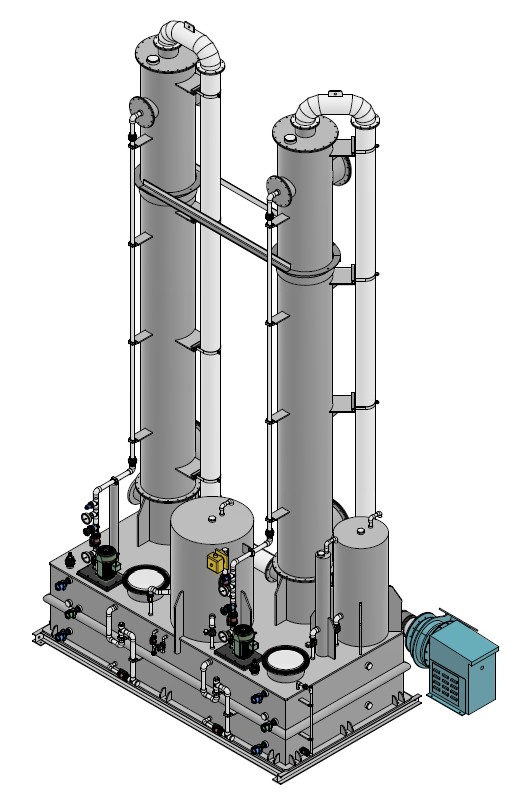

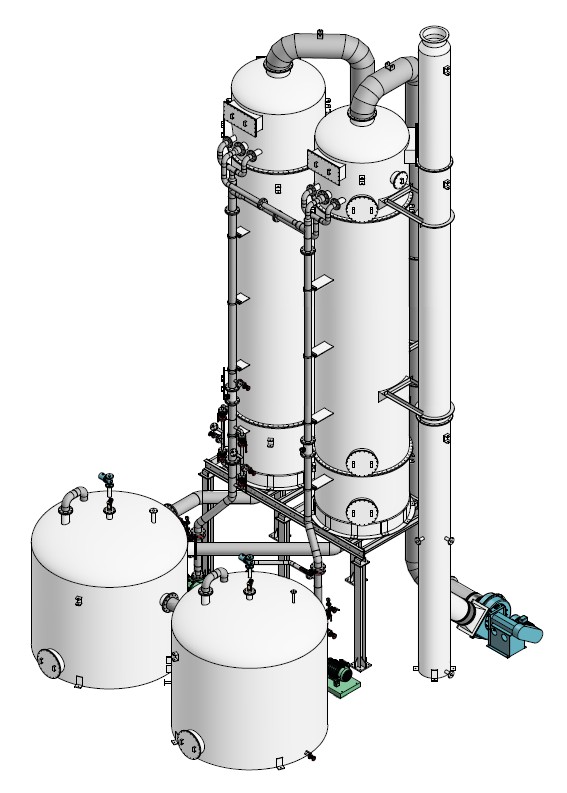

Twin Tower Air Scrubber Serves Dual Purpose

Using pilot-scale Army data for scale-up, AAT designed a robust twin-tower FRP system with redundant pumps, PP-lined piping, and full instrumentation to safely handle routine low-level ventilation and catastrophic phosgene releases. Commissioned in fall 2014, the package provides rapid reagent delivery, thermal management, and the ultra-high removal efficiency required for this extreme scenario.