Dry Air Scrubber for Propylene Oxide

Problem: Unverified scrubber performance for Propylene Oxide left uncertainty about safe, effective abatement methods.

Solution: AAT conducted controlled bench-scale testing confirming Safe-Cell II dry scrubbers achieve over 99.99 % PO removal with no safety concerns.

Background

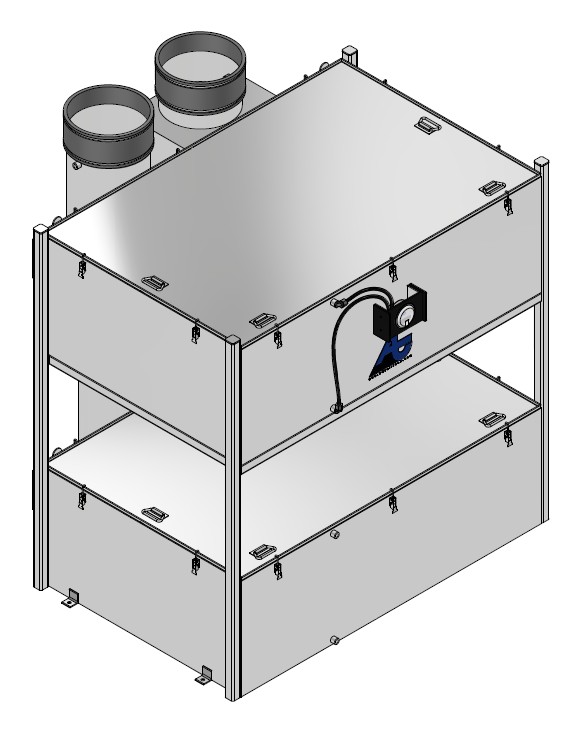

For decades, Advanced Air Technologies, Inc. has been the leader in air scrubber technology for abatement of Ethylene Oxide (EtO) emissions. In fact, AAT, Inc. was founded in 1987 on a unique dry scrubbing, chemi-sorption process for EtO. The result is a series of fixed bed “Safe-Cell II” dry scrubbers, consisting of the DR-490, DR-50, and DR-MAC-150. The DR-490 is the staple for commercial scale aeration exhaust, while the DR-50 is used on exhaust from small hospital sterilizers. The DR-MAC-150 is a new portable scrubber for removing low-levels of EtO from ambient air. Over the years, AAT, Inc. has refined its designs and developed detailed models from full-scale as well as bench-scale testing. Of recent interest is sterilization processes utilizing Propylene Oxide (PO). Important properties of PO having an impact on dry scrubber performance include its reactivity, molecular size and weight, and diffusivity in air, all of these being quite different for PO as compared to EtO. Theoretically, some properties of PO would tend to enhance dry scrubber performance, while others would tend to have negative impact. To be certain how Safe-Cell II technology would work on PO, AAT, Inc. rose to the task of carrying out bench-scale testing.

Test

AAT, Inc. designed and built a portable test station consisting of a pressurized cylinder of 4500 ppmv of PO in Nitrogen, pressure regulator, rotameter, test cell, and portable PO analyzer (0-50 ppmv). The test cell was packed with the AAT, Inc. dry air scrubber media. Gas was flowed through the test cell at a fixed rate set on the rotameter, and the concentration of PO in the Nitrogen stream exiting the cell was continuously monitored using the analyzer. At the beginning of the test, the outlet concentration was expectedly near zero, corresponding to essentially 100% removal of the PO by the fresh media. The capacity of the media is determined by measuring the amount of PO that can be treated while still achieving 99% removal efficiency.

Result

The results of the test were very encouraging. A second test was conducted as well with nearly identical results. The measured capacity to 99% removal of PO is only slightly less than that of EtO. Fresh media removal efficiency of PO was 99.991%, as compared to 99.995% for EtO. Also, there was no observable temperature increase in the cell or gas, eliminating any safety concerns about an exothermic reaction. The depth of media and the superficial velocity of the gas in the cell were designed to be identical to a typical full-scale unit, thereby reliably predicting the performance of a commercial-scale dry air scrubber. The bottom line is that AAT, Inc. Safe-Cell II dry scrubbers very effectively abate PO emissions, doing the job of keeping our air clean.

Contact & Location

Advanced Air Technologies, Inc. is located in Corunna, Michigan, 30 minutes east of Lansing. Our offices are open Monday through Friday, from 8:00am to 5:00pm Eastern Time (UTC-05:00 Eastern US).

We invite your inquiry and the opportunity to be of service.

Advanced Air Technologies, Inc.

300 Sleeseman Drive

Corunna, Michigan 48817-1078

(Michigan) USA

Phone: +1 (989) 743-5544

Email: sales@advairtech.com